Dynamic Sealing Solutions

Radial Shaft Seals, Butterfly Valve Seals, Diaphragms and many more

Dynamic Sealing Solutions for the Food & Beverage Industry

Dynamic seals are used in applications with motion between the hardware component and the sealing solution. The motion can be rotary, translatory, reciprocating or oscillating. Effective dynamic seals need to maintain a balance between the sealing force, minimize the friction and furthermore prevent leakage.

Portfolio of Dynamic Sealing Solutions

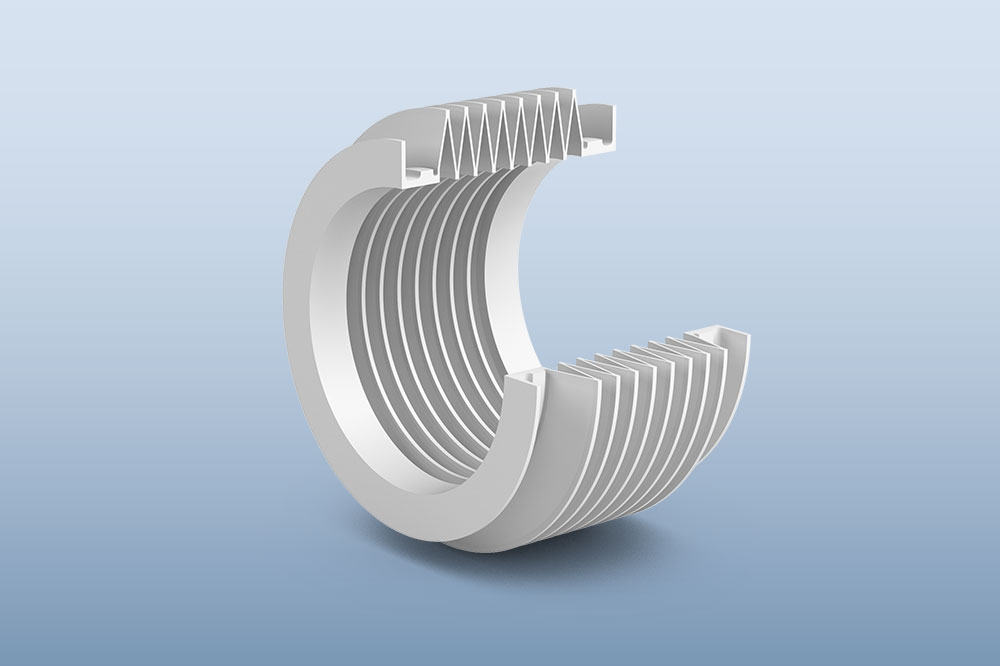

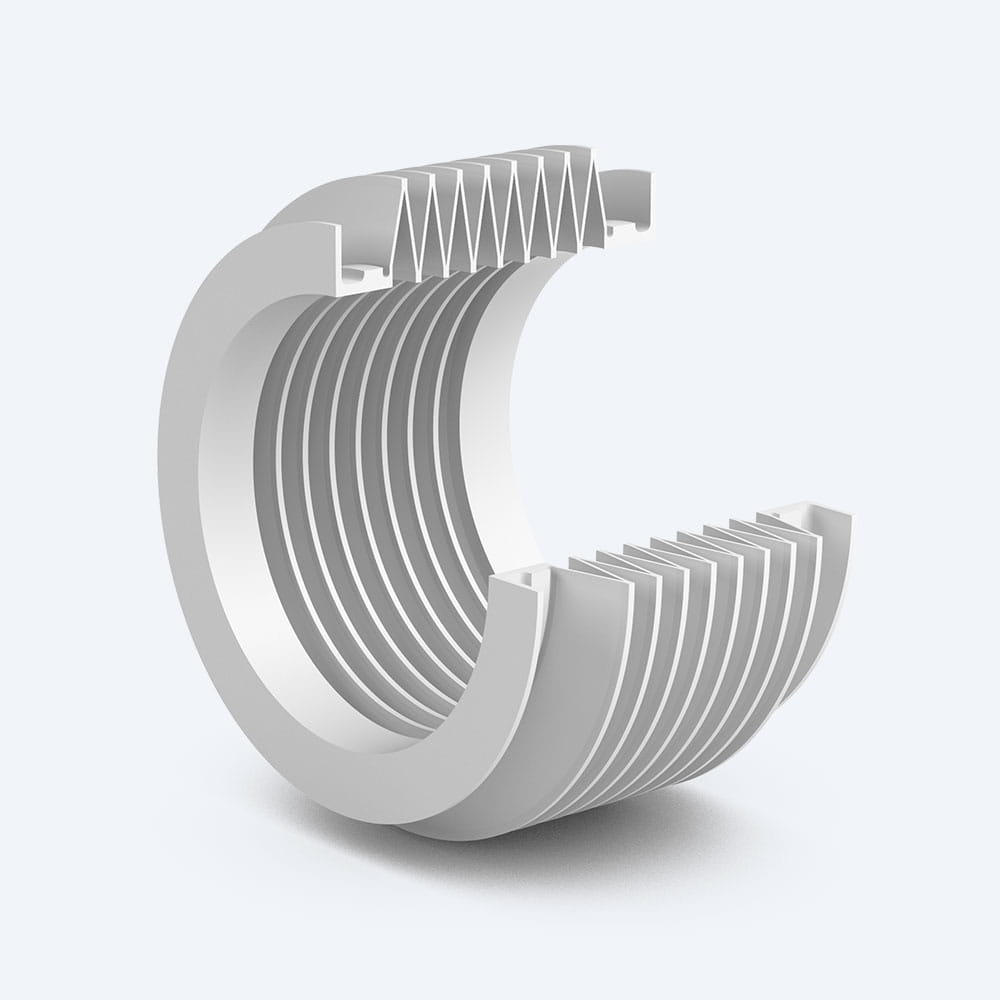

Bellows

PTFE bellows can be used to protect moving machine parts, to compensate for movements, vibrations and misalignments, as well as to circulate gases and liquids. They are available in virtually any size (below 10 mm on request). Due to our machining-based production process, our bellows are available in short order and provide good price-performance ratio, even for single parts. For the food and beverage industry, we use high-quality PTFE materials that comply with all relevant regulations.

Product Benefits

-

Extremely media and temperature resistant

-

Large range of diameters available

-

Customer-specific solutions

-

Reliably prevents media contamination

-

Range of applications includes compensation, parts protection, and liquid circulation

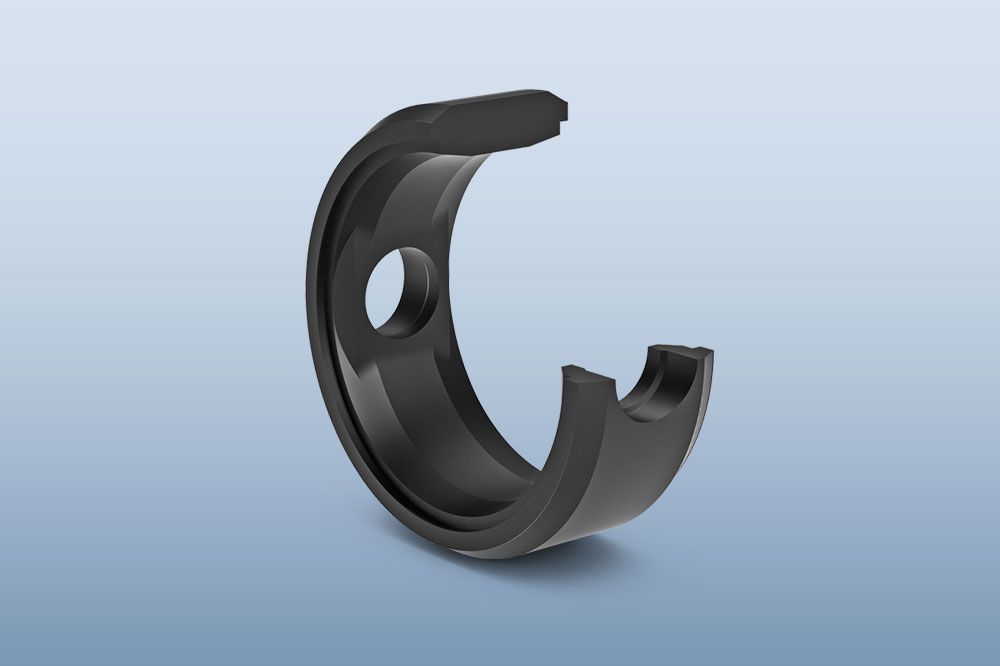

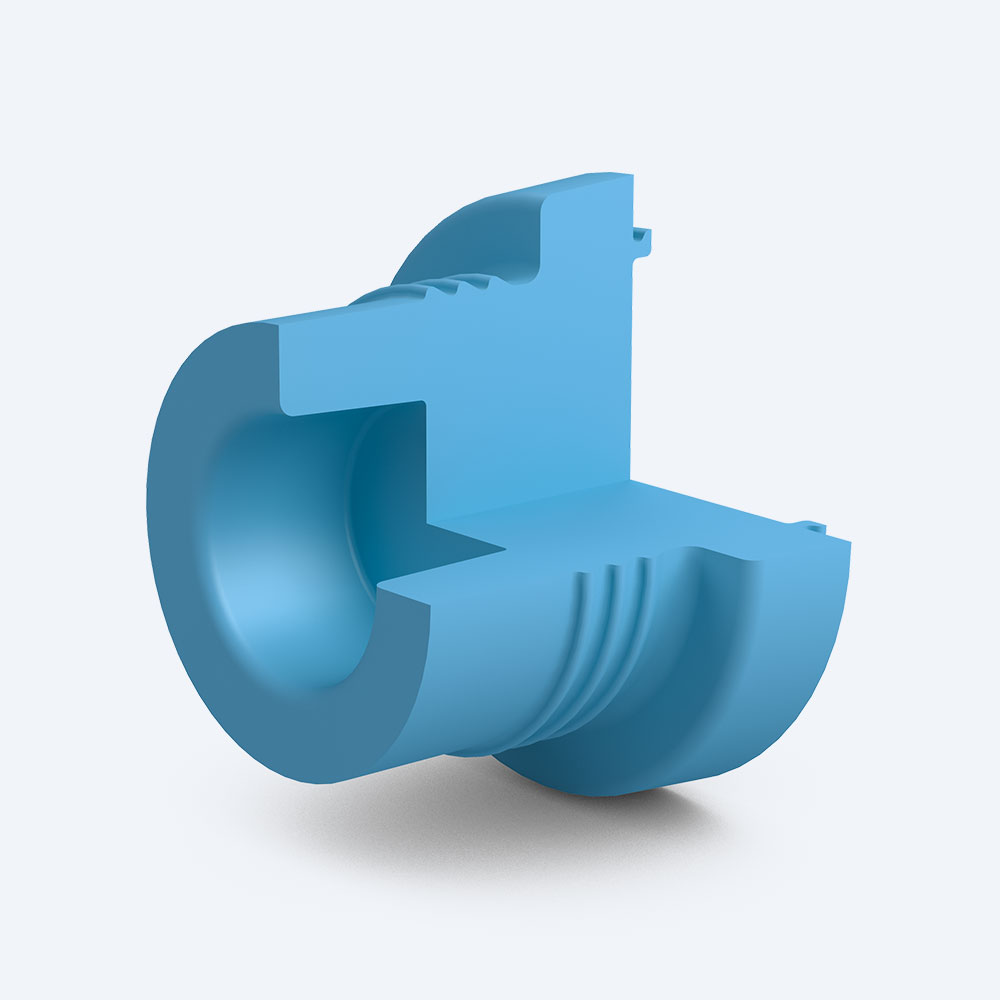

Butterfly Valve Seals

Thanks to the different materials from which they are made, Freudenberg Sealing Technologies’ butterfly valve seals are suitable for the special requirements of the food and beverage industry. Their properties include resistance to aqueous media and CIP/SIP cleaning processes as well as to high temperatures and media such as fat and nitric or formic acid. For hygienically demanding applications, dead-space-free variants that comply with Hygienic Design standards are available. Freudenberg Sealing Technologies has developed special materials for butterfly valve seals, such as EPDM materials that are highly resistant against abrasion.

Product Benefits

-

Available in a broad range of high-performance materials

-

Individual designs tailored to your needs

-

Special variants like low-friction or Hygienic Design versions

-

Special design allows easy installation

-

Patented design for maximal operating cycles and minimal abrasion

Customer-Specific Parts

Unique applications require individually designed sealing solutions. Flavor transfer, leakage due to compatibility problems, and missing certifications are common challenges in the food and beverage industry. Customer-specific parts from Freudenberg Sealing Technologies are made of high-performance materials in order to fulfil all these requirements. They are manufactured with materials that correspond to the application and that are resistant both to the product itself and to all common cleaning agents. In addition, our specialists offer professional consulting on these issues. We design customer-specific parts for special filling heads and valve seats for beverage systems, double-seat and sterile valves, separators, and many more types of equipment.

Our Freudenberg Xpress® service greatly accelerates the process of prototyping, as machining technology makes it possible to produce several functional samples. Plus, we conduct economical field tests at our test plant to find the best solution tailored to your processes in the fastest possible time.

Product Benefits

-

We are the global leader in product design and material expertise

-

Highest quality

-

High media and temperature resistance

-

All relevant food and beverage material certifications

-

Outstanding material, product, and application expertise

-

Individually designed components

-

Extensive testing possibilities

-

Innovative simulation and analysis methods

-

Materials prevent flavor transfer

Download Success Story Tetra Pak®

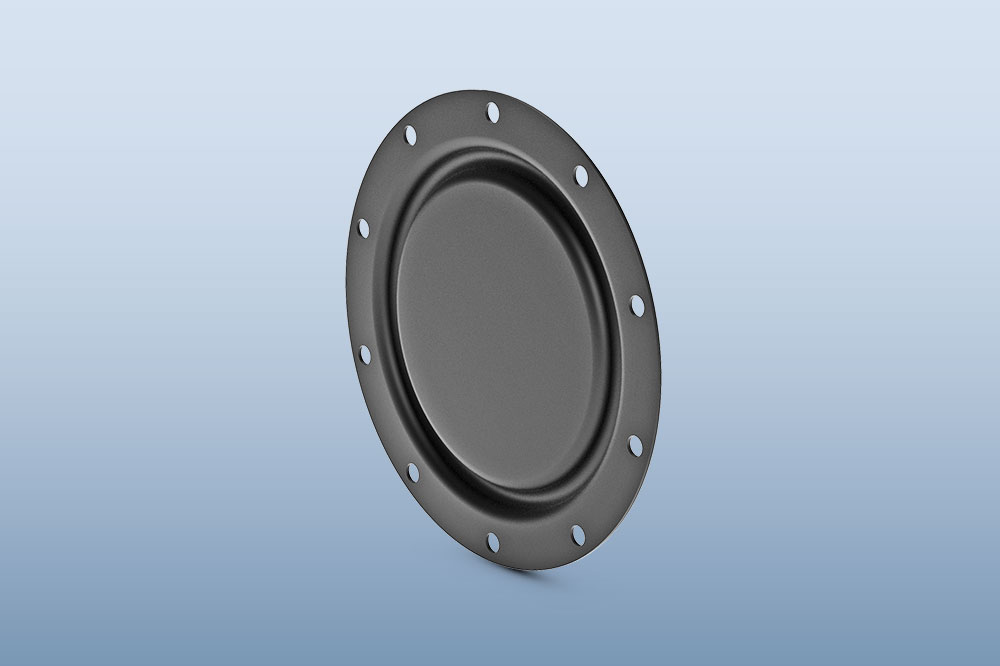

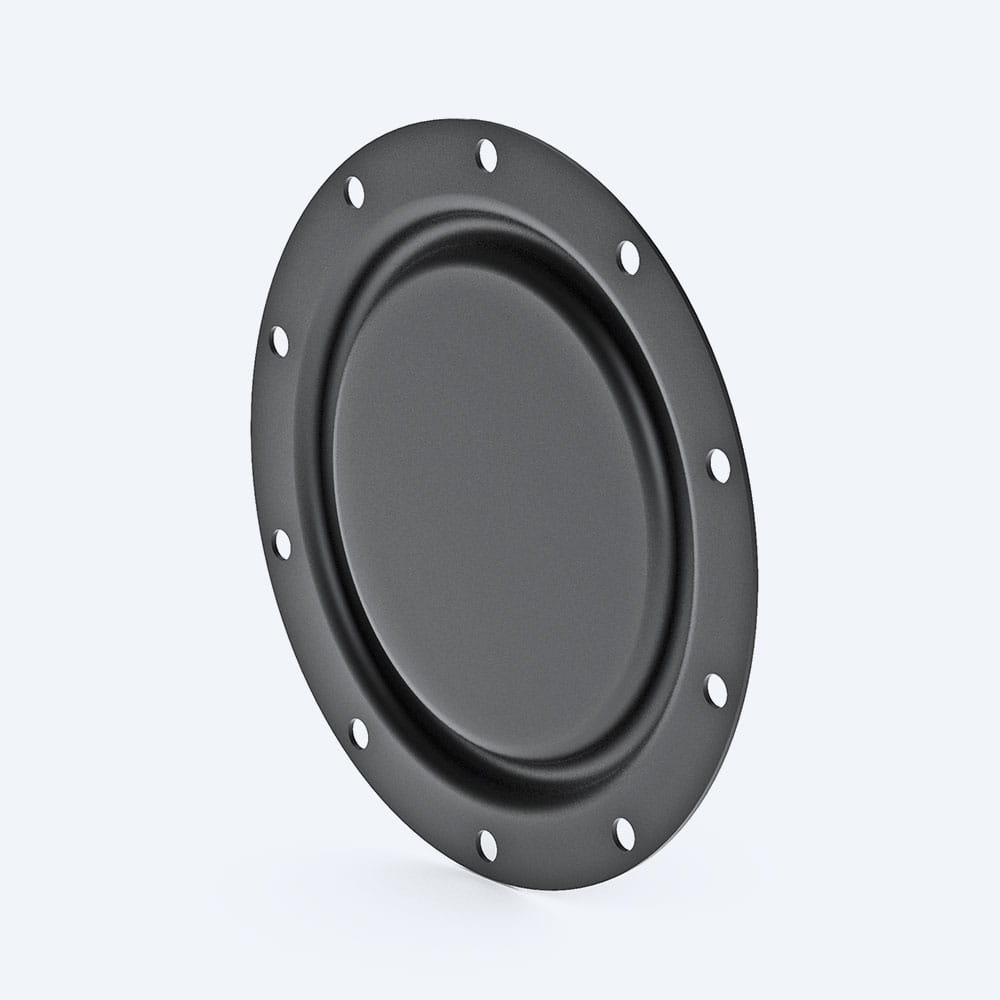

Diaphragms

Diaphragms are very flexible sealing elements that regulate and switch using pressure. Freudenberg Sealing Technologies offers diaphragms made from specially developed sealing materials for the food and beverage industry, such as 70 EPDM 291 and Fluoroprene® XP. Our sealing experts are able to design diaphragms tailored to your individual requirements. For example, fabric reinforcements, metal inserts, or foil layers can be added to vary the diaphragm’s performance. With their diverse functions, diaphragms may be used in a broad range of applications, such as fittings, pumps and compressors, actuator valves, and regulators.

Product Benefits

-

Broad range of functions and applications

-

Custom-designed

-

Long service life

-

Extreme media resistance

Guide Rings and Wipers

Freudenberg Sealing Technologies’ guide bands are available in a range of materials that ensure low wear and a minimal extrusion propensity. Special materials conform to legislation specific to the food and beverage industry and can be used even in direct contact with media. They include PTFE Y005, which is made of a pure, virgin, high-grade PTFE, as well as other PTFE variants that include fillers. The materials for guide bands are also extremely resistant to CIP/SIP cleaning media and processes.

Freudenberg Sealing Technologies offers wipers made from materials that conform to food and beverage standards, allowing the wiper to be in direct media contact. Wipers protect the interior from external influences and remove process media residue. Individual designs mean that the wipers can be flexibly adjusted to your application and requirements.

Product Benefits

-

Extremely media-resistant, e.g. to CIP/SIP media

-

Very low extrusion tendency

-

Long service life thanks to low wear properties

-

Range of available sizes

-

Special variants for hygienically demanding applications

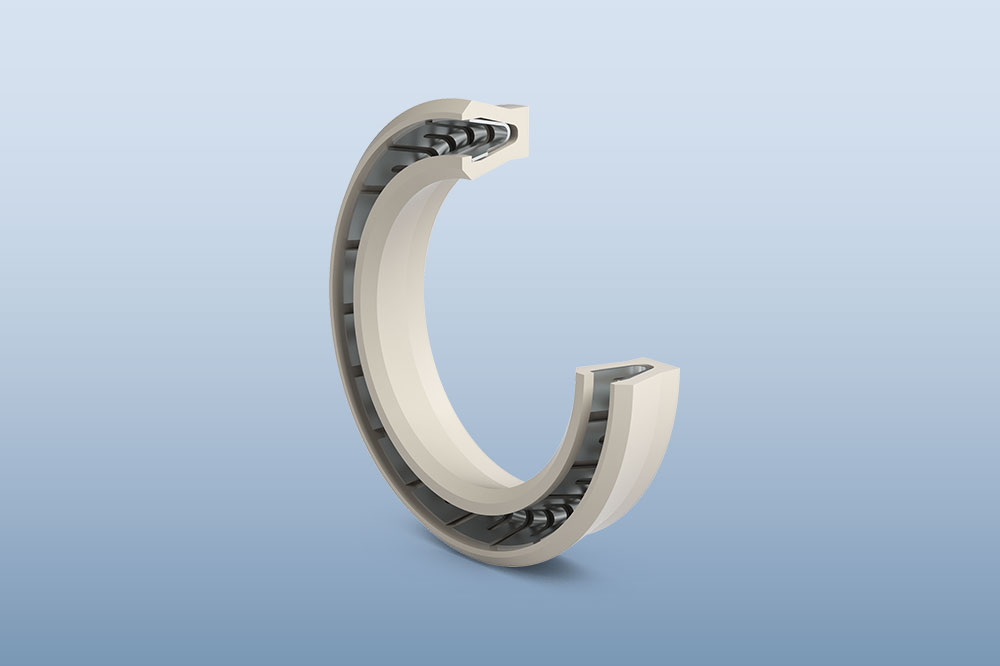

Radial Shaft Seals

The patented shape of the original Freudenberg Simmerring® provides great functional reliability and safe production processes. Freudenberg Sealing Technologies offers special designs for the food and beverage industry, including the Radiamatic® HTS II, the Simmerring® BlueSeal, and the Simmerring® B2PT. Their key feature is their resistance to media and extreme temperatures – the substances only come into contact with high-performance materials like PTFE and Fluoroprene® XP, which conform to all relevant legal standards. Available in different options, including variants that meet Hygienic Design standards, radial shaft seals lend themselves to various applications – in mixers, grinders, and bottling systems.

Product Benefits

-

Variable and reliable use

-

Hygienic Design variants – no dead spaces or gap extrusion

-

Excellent media and temperature resistance due to high-performance materials

-

Broad range of designs

-

Low friction and anti-adhesion

Download Brochure "Sealing Solutions for Drive Shafts in the Process Industry"

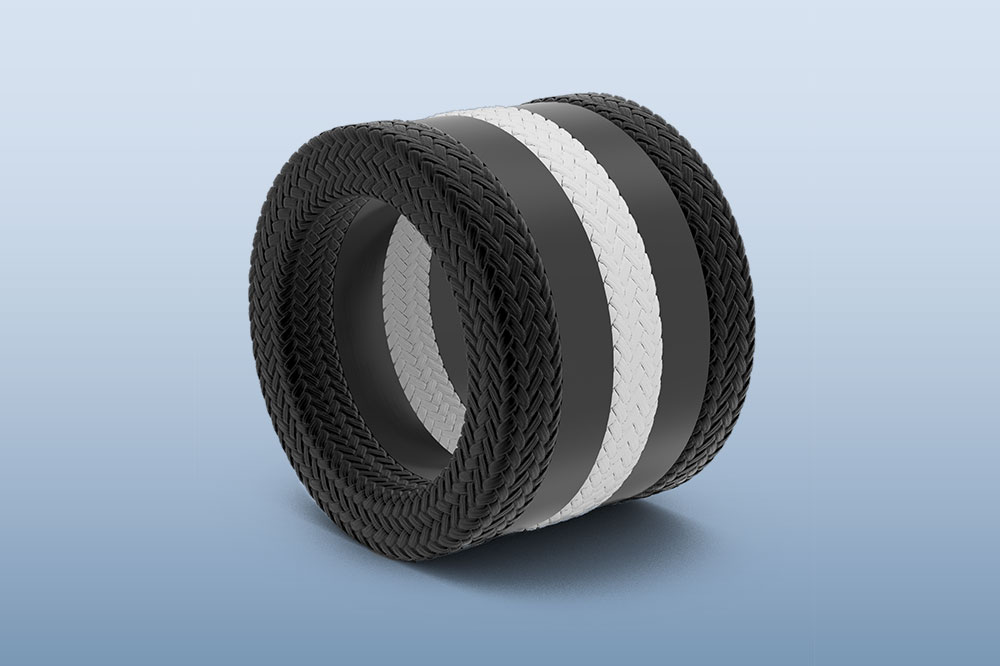

Stuffing Box Packings

Freudenberg Sealing Technologies offers special stuffing box packing variants for the food and beverage industry. One example is Valtec, which is highly resistant to solvents, acids, and alkaline media. Valtec consists of a PTFE-impregnated nonwoven that is FDA-compliant, making it suitable for applications involving contact with food. In addition, stuffing box packings provide an extremely broad temperature range. Different types of stranding allow modifications for different applications, like valves, mixers, homogenizers, pumps, and fittings.

Product Benefits

-

Extremely media resistant

-

Self-amplifying sealing function under pressure

-

Range of different designs

-

Resistant to high pressures

-

Broad temperature range (-200 °C up to +400 °C)

-

Special variants for compliance with TA Luft

-

Several variants for the food and beverage industry

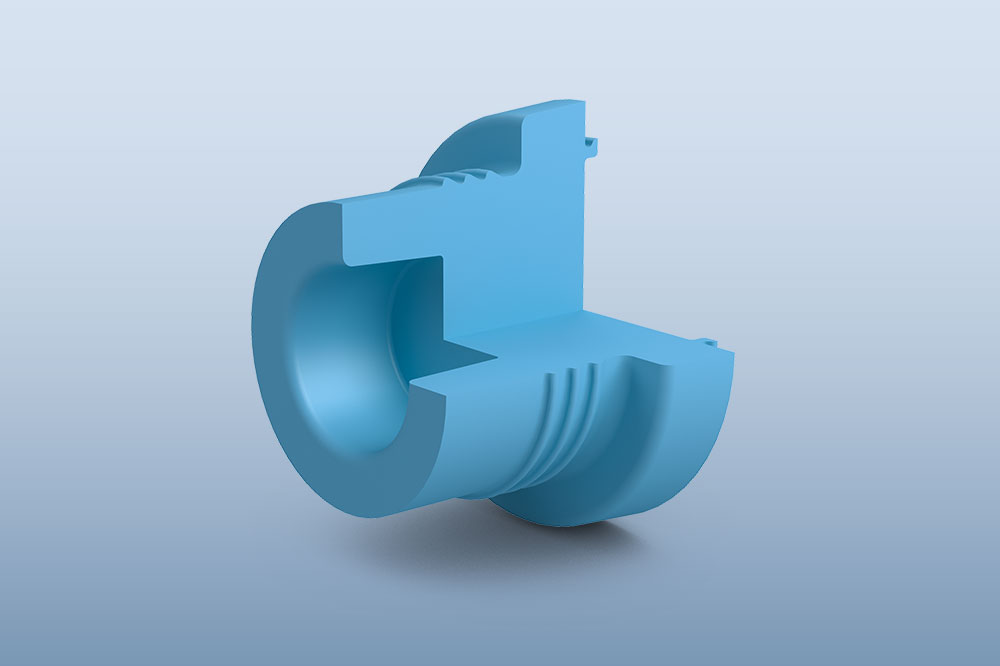

U-Packings, Rod Seals and Piston Seals

Our U-Packings made of PTFE are highly media and pressure resistant – even in contact with especially aggressive media. This makes them highly dependable sealing elements that ensure outstanding longevity. As U-packings can be machined, they are available in virtually any size. The corresponding spring is made from endless material, so U-packings can be provided very fast.

Rod and piston seals are made to provide reliable sealing for hydraulic applications. The experts at Freudenberg Sealing Technologies support you with the right sealing solution for each application. These products are tailored to the needs of the food and beverage industry and are resistant to high pressures and aggressive media as well as high temperatures.

Product Benefits

-

Extremely media and temperature resistant

-

Special variants for high-pressure or hygienic applications

-

No stick-slip effect

-

Long service life

-

Available in a wide range of dimensions thanks to flexible manufacturing processes

V-Seal Set Packings

V-Seal Set Packings are used for applications with translatory motion or slow rotational movement, like the spindles of regulation valves or parts of mixers. As they are made of PTFE or PTFE-impregnated fabric, they are resistant to temperature ranges up to +250 °C as well as to many common chemicals. Due to their low friction, v-seal set packings are a good alternative to stuffing box packings. They are available in standard or customized designs.

Product Benefits

-

Wide portfolio that covers all applications, machine designs, and installation spaces

-

For high-pressure applications

-

High temperature resistance

-

High chemical resistance

-

Low friction

CHEMICAL RESISTANCE GUIDE

Still lost in spreadsheets?

Just a few clicks and you know which material is resistant to which process media.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new