Company

Company Introduction

Freudenberg is a global, family-owned company with different business groups that all operate individually in various industries. The aim behind this segmentation is to be as close as possible to the customer. In order to guarantee quick reactions to current market trends, the company has many research and development facilities.

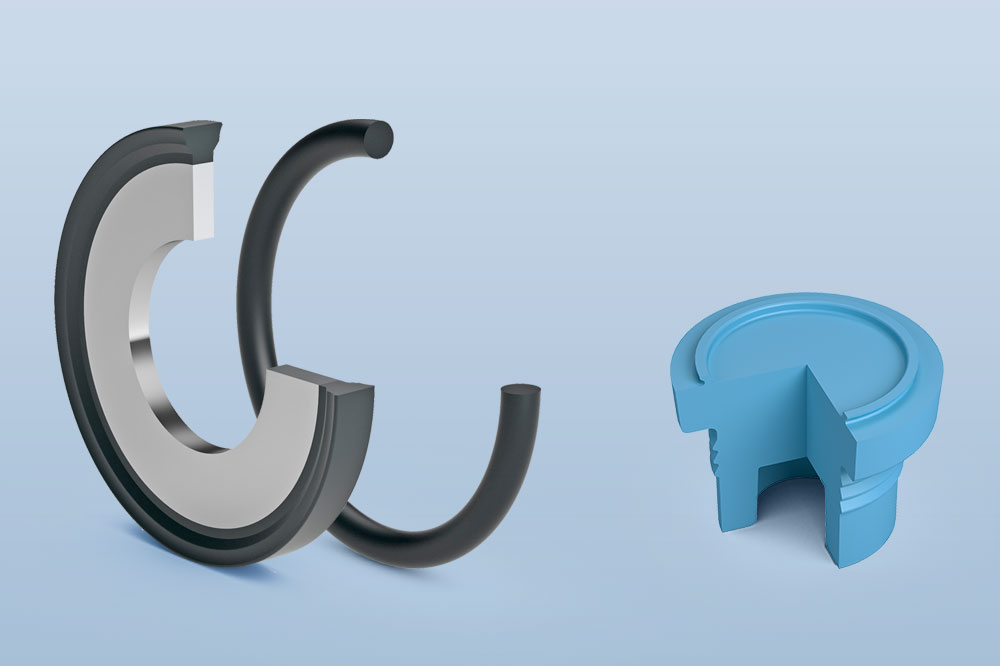

Freudenberg Sealing Technologies is the biggest business group within the Freudenberg Group. Together with its partners of the NOK Corporation, it is a global provider of premium sealing solutions. There are not only local production sites all over the world, but also local experts for each region. Standardized seals as well as customer-specific parts are included in the comprehensive product portfolio.

Brand History

From Leather to Levitex

An entrepreneurial tradition dating back more than 175 years. The history of the Freudenberg Group.

Three key themes run through the Freudenberg Group’s history from its founding as a small tannery in 1849 down to the present: innovation, internationalism and quality.

At the start, the tannery solely manufactured high-quality calf leather, then specializes in innovative patent leather a year after its founding, and later develops chrome tanning, doing business far beyond Germany’s borders very early on.

The company’s diversification begins with the invention of Simmerrings in 1929 and its entry into the sealing business. Freudenberg finds answers to the challenges of each respective era and develops new markets, new industries and new regions through innovation. Beginning in 1960, the international collaboration with the NOK Corporation of Japan is ground-breaking, guiding the sealing business into global channels.

Your Advantages With Freudenberg Sealing Technologies

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new