Innovations

Innovative Sealing Developments for more Hygiene, Safety and Predictive Maintenance

Innovations for the Food & Beverage Industry

Innovation in the pursuit of perfection and to keep ahead of trends and new requirements is one of our core values and is deeply anchored in our DNA. Our product and material experts continuously work on improving existing solutions and develop completely new ideas. In keeping with our company slogan “Innovating together”, this often happens in close cooperation with our customers.

Contact our experts and discuss your individual needs.

Innovations

75 FKM 239961

Peroxide cross-linked Fluoro Rubber

The new fluorinated FKM from Freudenberg Sealing Technologies is particularly suitable for food applications with high temperatures or aggressive media where other elastomers such as EPDM or HNBR reach their limits. In addition, the material is predestined for contact with pure citrus juices, dairy products and aromatic oils in the beverage industry. At the same time, it meets the latest regulatory requirements for materials in the food industry with direct product contact and offers high purity.

Product Benefits

-

Long-term certification according to EG (Reg.) 1935/2004, FDA § 177.2600, USP Chapter 87 (in vitro) and 3-A® Sanitary Standards

-

Material with high purity standards that meets the latest requirements of the food and beverage industry

-

Excellent media and temperature resistance

HNBR Materials for the Food and Beverage Industry

With the help of extraction tests, Freudenberg Sealing Technologies has tested and certified some of its HNBR materials according to the European EU (Reg.) 1935/2004 as well as the US-American FDA. They can now be used in food and beverage plants without any concerns; also in direct contact with the end product. Additionally, these sealing materials are resistant to CIP/SIP and fatty media. As usual for HNBR materials, they are especially suitable for applications with high mechanical stress. They are available for O-rings and customer-specific parts – also hygienically designed.

Product Benefits

-

Reliable certification according to EU (Reg.) 1935/2004 and FDA

-

Resistance to CIP/SIP and fatty media

-

Very good physical resilience

-

Hygienic design

-

Available as customized sealing products

Product Examples

-

O-rings made from 85 HNBR 181071 and 75 HNBR 231142

-

Customer-specific parts made from 70 HNBR 254067, 75 HNBR 253436, 85 HNBR 216553 and 85 HNBR 181071

New Product Line for Hygienic Plants in the Process Industry

Cleanliness, hygiene, conformity and durability – the process industry poses a variety of challenges to seals. They must have a high degree of purity and comply with hygienic design standards. With the new product line for hygienic plants in the process industry, Freudenberg Sealing Technologies offers a unique product portfolio for hygienic applications. This includes not only the Hygienic Pressure Seal and Hygienic Forseal, which are made of the premium PTFE Quantum®, but also dead-space-free radial seals for seat valves, radial shaft seals such as the Radiamatic® HTS II 9539 VL with an advanced sealing lip, shaft seals, butterfly valve seals, Hygienic Usit® rings, clamp seals with support ring and aseptic O-rings.

Hygienic Pressure Seal

The Hygienic Pressure Seal is the optimal solution for applications where high temperatures and pressures prevail. The combination of the high-performance elastomers Fluoroprene® XP or EPDM and the premium PTFE Quantum® makes this product absolutely unique.

Product Benefits

-

Prevention of dead space by a flat contact surface to the process medium

-

Low friction, reduced wear and increased service life

-

Resistant to high pressures up to 150 bar

-

Secure fit and minimum contact surface with the medium

-

Good dry running properties

-

High media and temperature resistance

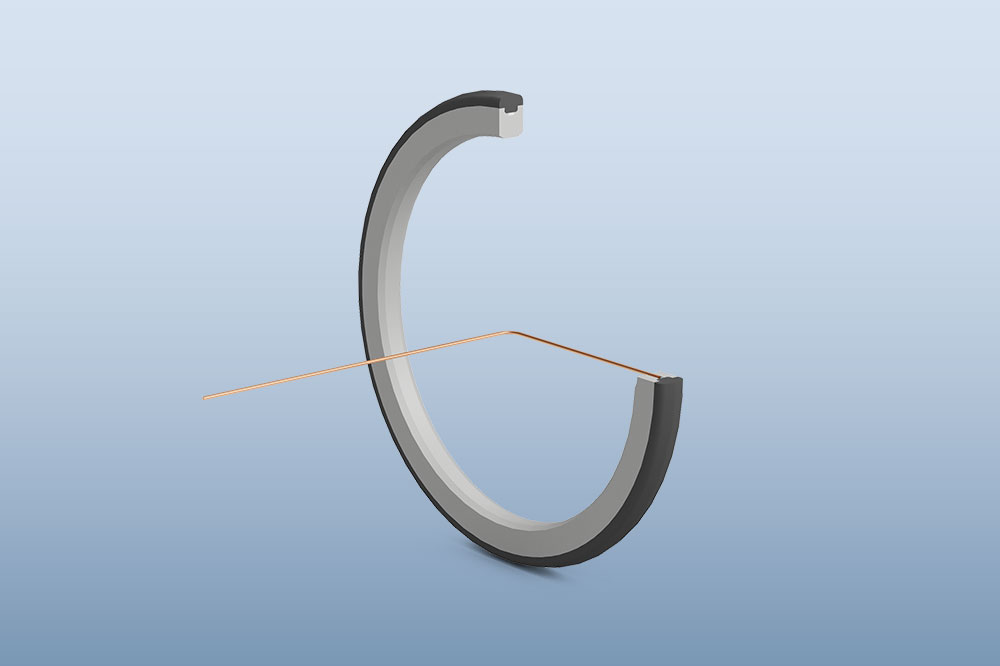

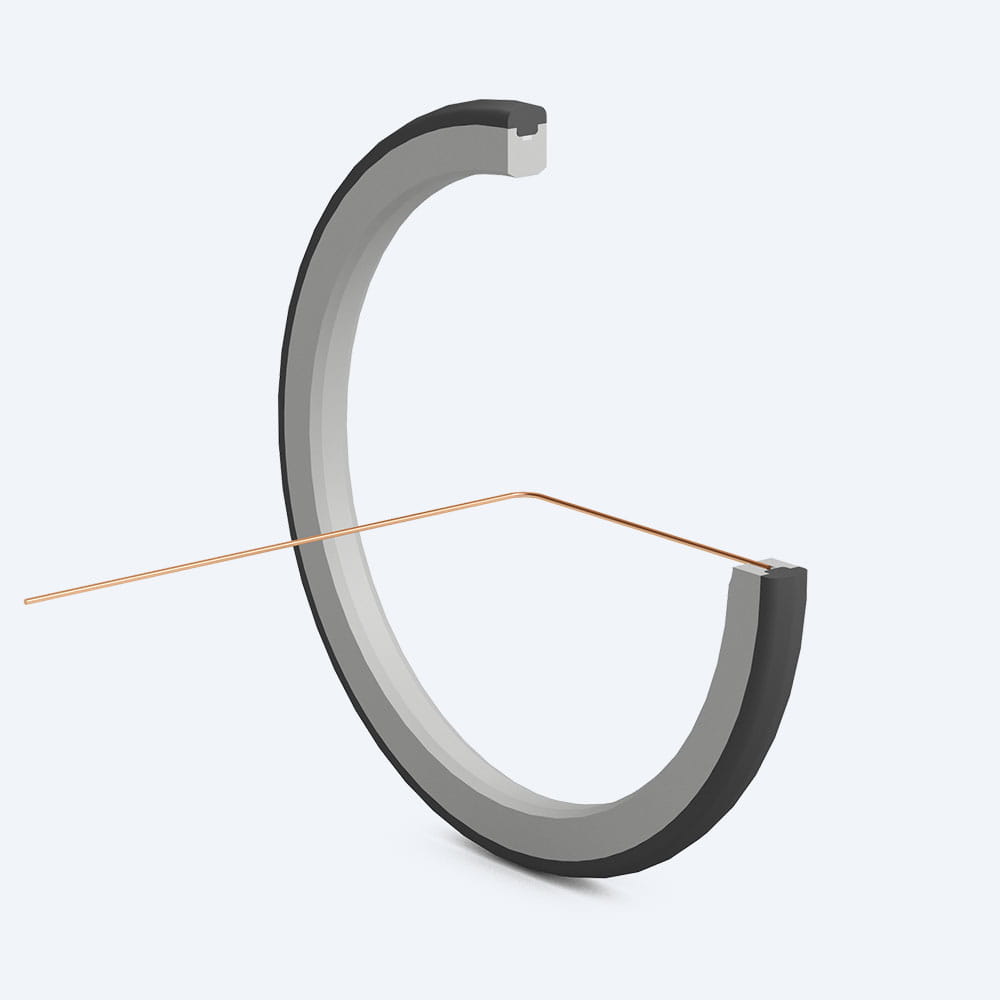

Hygienic Forseal

The Hygienic Forseal is a combination of a groove ring made of the premium PTFE Quantum®, activated by a pressure ring made of Fluoroprene® XP or EPDM.

Product Benefits

-

Replacement of the conventional stainless-steel spring with dead space due to the principle by an elastomer pressure element

-

Flat contact surface to the process medium prevents dead space

-

Low friction, reduced wear and increased service life

-

Good dry running properties

-

High media and temperature resistance

-

Mounting in undivided installation space possible

-

Customer-specific designs, such as a double seal and an anti-rotation device possible

Download Brochure "Product Line for Hygienic Plants in the Process Industry"

Food Conforming Materials for Global Use

Since 2016, China has had its own requirements for the food and beverage industry: GB 4806 and GB 9685. Freudenberg Sealing Technologies has developed special sealing materials that comply not only with these new standards, but also with global requirements such as those issued by the American FDA (Food and Drug Administration) or the European EU (Reg.) 1935/2004. Currently the portfolio includes EPDM-compounds (75 EPDM 386, 70 EPDM 382, 85 EPDM 387) silicones (70 VMQ 117055, 60 VMQ 117117) and plastics such as PTFE V037, Polyamide 12G 37599 and Polyethylene E083. We are happy to support you and your business partners in China with your individual requirements.

Product Benefits

-

Global compliance with food and beverage industry requirements

-

Many tested and certified materials

-

Production possible with Freudenberg Xpress®

Predictive Maintenance

With the goal of proactively planning maintenance intervals and thus preventing costly equipment failures, products and services from Freudenberg Sealing Technologies enable predictive maintenance. In addition, precise long-term forecasts can prevent leaks.

TFor example, the Freudenberg Smart Seal continuously displays its wear level. This information can be linked to system data, enabling the creation of a "digital twin." By taking into account factors such as temperature, switching cycles, and media influence, it is possible to conduct simulations on service life – a crucial capability for predictive maintenance and a core component of industry 4.0. The Freudenberg Smart Seal is the only system that allows direct wear measurement on the seal itself, significantly improving overall equipment effectiveness.

Freudenberg Sealing Technologies is the only seal manufacturer with a validated process for product simulation using proprietary material models. This process shows mechanical and chemical property changes over a defined period. Thanks to specially developed concepts, extrapolation errors can be minimized. Using a physical model, essential aging effects can be integrated into FEM simulations. As a result, virtual component representation saves development time and eliminates the traditional trial-and-error methodology.

Benefits

-

Proactive planning of maintenance intervals

-

Avoidance of batch contamination and consequential damage

-

Reduction in the amount of personnel required for maintenance

-

Flexibility through individually adjustable intervention limits

-

Time and cost savings

In our video, you can see the Freudenberg Smart Seal using the example of an intelligent seal in a valve.

CHEMICAL RESISTANCE GUIDE

Still lost in spreadsheets?

Just a few clicks and you know which material is resistant to which process media.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new