Filling Units

Sealing Solutions for Filling Units

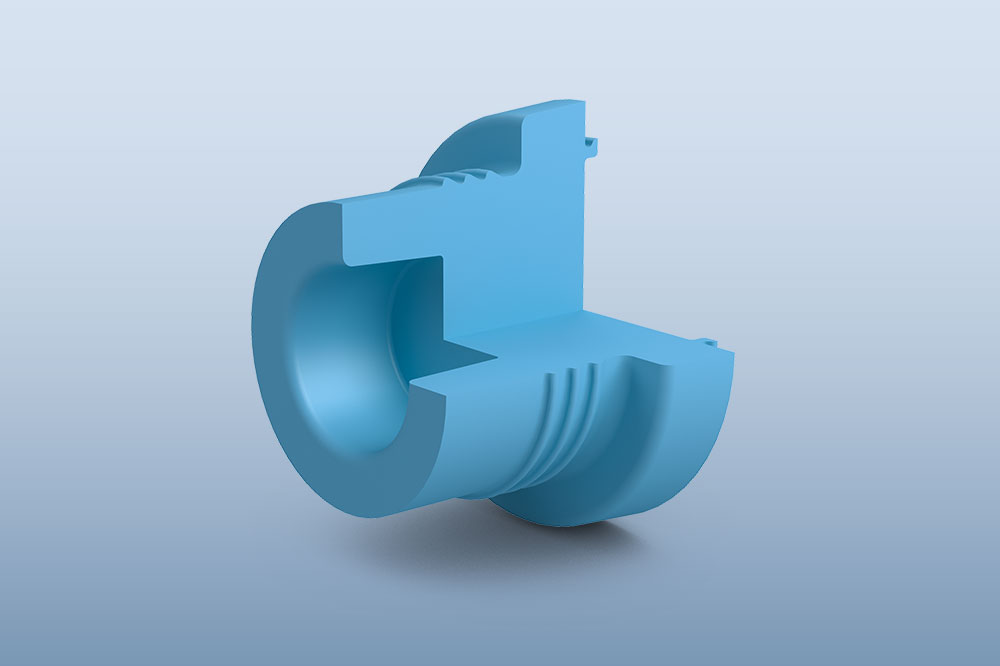

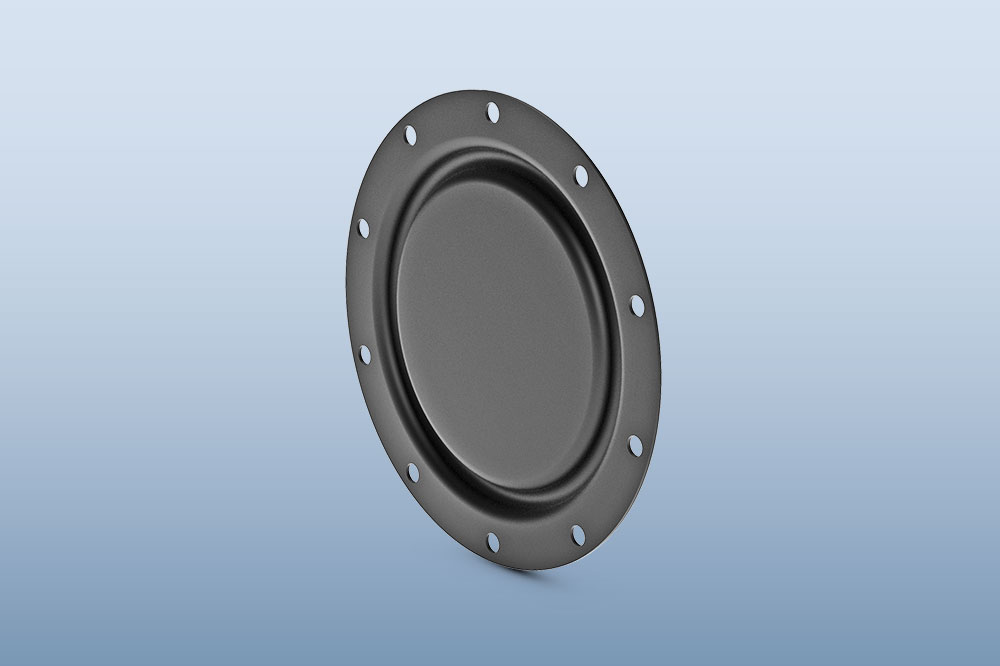

To meet the demanding requirements of filling units, such as fill heads in filling plants, Freudenberg Sealing Technologies has developed special sealing solutions made of premium materials for the food and beverage industry. Because the filled product comes into direct contact with the seals, the sealing solutions need to be hygienic. This means that seals have to be designed according to Hygienic Design standards and the material needs to comply with all relevant legal standards such as those issued by the FDA (Food and Drug Administration) and EU (Reg.) 1935/2004.

When the beverages being filled are switched over, this can lead to flavor transfer caused by the seals. Most of the standard sealing solutions on the market are unable to cope with this challenge. Freudenberg Sealing Technologies provides the specially developed sealing material Fluoroprene XP, which absorbs hardly any media and does not transfer it to the product being filled. In addition, it is highly resistant to most chemical media, cleaning agents, polar and nonpolar media and fat. The material also withstands the use of the most challenging flavors found in energy drinks and near-water products.

3D Animations

We show you our innovative sealing solutions

for filling units in the food and beverage industry.

Why Choose the Experts for the Food & Beverage Industry?

Related Products

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new