High-Performance Butterfly Valve Seals

High-Performance Butterfly Valve Seals

As a technology leader, Freudenberg Sealing Technologies is the specialist for innovative sealing solutions in the process industry. Our focus is on innovation and partnership. Together with our customers, we develop tailor-made materials and sealing products according to segment- or customer-specific requirements, such as approvals, Hygienic Design and CIP/SIP processes.

Benefits at a Glance

-

Unique hygienic design with high pressure resistance, improved friction and long service life

-

Simplified assembly

-

Premium sealing materials that have all relevant approvals and conformities from FDA to BNIC

-

Cost and time savings thanks to validation tests under real conditions on the in-house test bench

The Customer

Definox is a French valve supplier for applications in the food, beverage, pharmaceutical, cosmetics and pet food industries. The company places particular emphasis on partnership relationships with its customers and suppliers in order to develop innovative technologies. Its wide range of valves is complemented by a unique portfolio of services and an augmented reality mobile application called „id Definox“.

Segment & Application

Our customer Definox specializes in innovative high-performance valves tailored to the process industry with the appropriate certifications. These include butterfly, shut-off, changeover, mixproof and aseptic valves.

Development & Solution

Definox needed an optimized, customized sealing solution in the form of a butterfly valve seal to match its portfolio of high-quality, high-performance valves. The company contacted our experts due to their positive experience with O-rings made of the premium material 70 EPDM 291 from Freudenberg Sealing Technologies. The goal was to work in partnership to develop just the right solution for the current market situation.

A wide range of validation tests were carried out in the first phase of the project on Freudenberg’s in-house test bench in Weinheim. The reference dimensions were tested under real conditions, using original Definox valves. An optimization of the current design was thoroughly tested in-house and confirmed by the tangible results that were obtained after long-term runs. Furthermore, our experts were always on hand to provide comprehensive and clear advice. Due to the positive response to the newly developed sealing solution, Definox launched the second phase of the project: the gradual replacement of butterfly valve seals in existing valve types with products from Freudenberg Sealing Technologies.

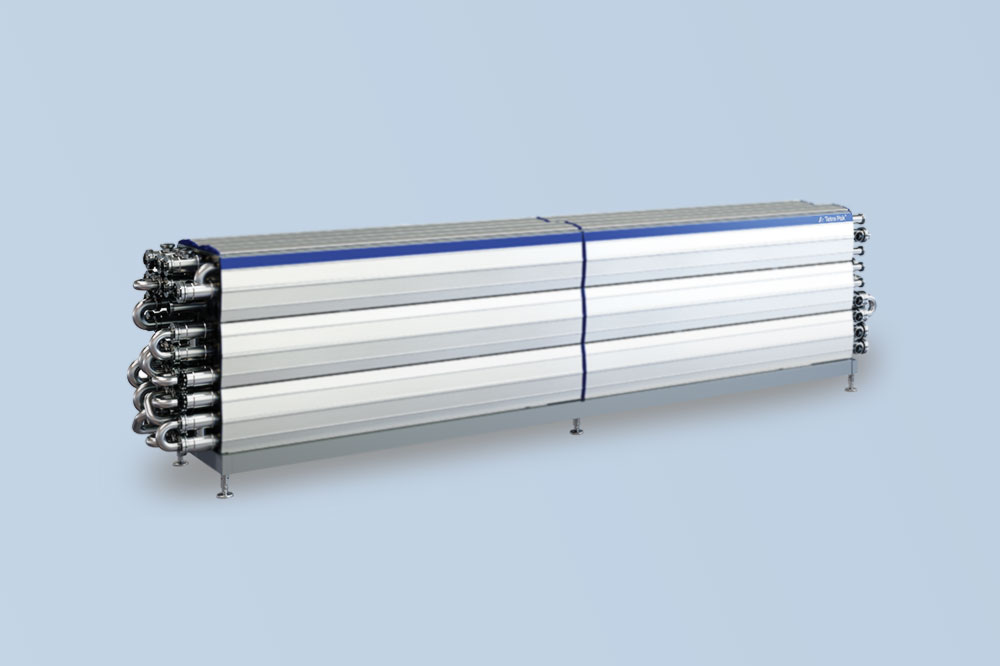

In a cooperative partnership with Definox, Freudenberg Sealing Technologies has developed a unique butterfly valve seal whose combination of wear-resistant materials and innovative design is tailored to the needs of the process industry. Besides very good pressure resistance, the new butterfly valve seal offers extremely low torque values The frictional behavior has been optimized, thus greatly reducing the friction values. Excellent pressure resistance can be maintained even after many switching operations. These modifications have resulted in a longer service life and higher reliability, even under challenging operating conditions. In addition, both Definox and the end customer benefit from easier installation. The new high-performance butterfly valve seal meets hygienic standards due to the elimination of dead spaces and improved cleanability, and has been certified in accordance with the strict guidelines of the EHEDG.

The three materials, 75 EPDM 253356, 75 Fluoroprene XP 41 and 75 HNBR 254067 comply with the standards of the American FDA (Food and Drug Administration) and the EU (Reg.) 1935/2004. 75 Fluoroprene XP 41, which is blue in color, was even tested at 121 °C and in vitro in accordance with USP Chapter 88 and certified as Class VI. It also meets the regulations of 3-A Sanitary and the French BNIC (Bureau National Interprofessionnel du Cognac). This plays an important role for Definox, as many of the valves produced are supplied to the spirits industry. The combination of the materials offers another advantage besides their excellent resistance to media and temperature: the different colors make it easier to distinguish between them during installation and maintenance, thus reducing the error rate.

Thanks to this partnership, an innovative sealing solution with optimal properties for use in the process industry has been developed.

Do You Already Know Our Other Success Stories?