Sealing Solution for High-Pressure Valves

Sealing Solution for High-Pressure Valves

As a technology leader, Freudenberg Sealing Technologies is the specialist for innovative sealing solutions in the process industry. Our focus is on innovation and partnership. Together with our customers, we develop tailor-made materials and sealing products according to segment- or customer-specific requirements, such as approvals, Hygienic Design and CIP/SIP processes.

Benefits at a Glance

-

Sealing solution conforming to Hygienic Design

-

Premium sealing materials including all relevant approvals and conformities

-

Fastest possible development in partnership without tooling costs, thanks to the Freudenberg Xpress® service

-

The only hygienic high-pressure valve system on the market which is certified to 3-A® Sanitary Standards

Customer

Bardiani Valvole Spa designs, manufactures and markets valves for sanitary applications from Italy all over the world, “Made in Italy “ from the design, to raw materials, to production – combined with a one to one service, reliability and accuracy.

Segment & Application

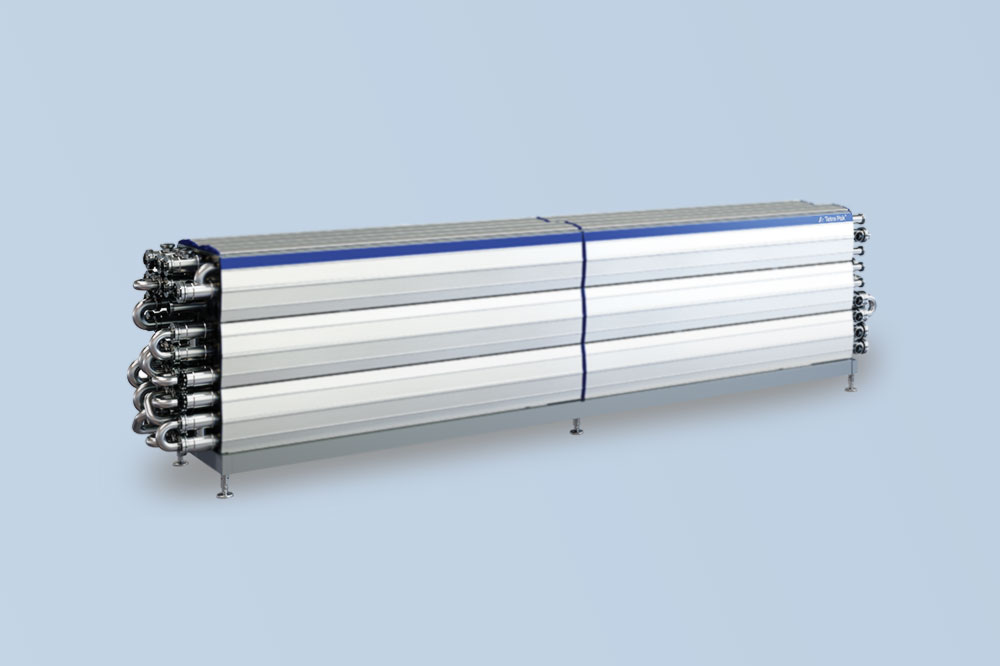

Our customer Bardiani Valvole developed a new and unique single seat valve for high-pressure applications in the food and beverage as well as pharmaceutical industry.

Challenge

For this newly developed valve, which is the only hygienic highpressure seat valve on the market, Bardiani Valvole was in need of a special, customized sealing solution. Therefore, the experts from Freudenberg Sealing Technologies were contacted with the aim of developing an appropriate solution in partnership.

The sealing solution in need was a main rod seal for valves in applications where pressure conditions of up to 150 bar occur. As the valves are used in the process industry, with direct contact to process media, the seal‘s design needed to conform to Hygienic Design standards, meaning that dead spaces had to be prevented. In addition, the new seal had to be designed to fit in the former generation of high-pressure valves.

To speed up the development process, it was decided to perform the validation tests based on machined samples, made from the original Freudenberg materials. With the expertise of the Freudenberg Xpress® service, the sample approval process could be done without incurring any tooling costs and within the shortest possible manufacturing time. The sealing materials used were already well known and appreciated by the customer as they had already proven their excellent chemical resistance and mechanical properties as well as complete range of approvals.

Solution

Together with Bardiani Valvole, Freudenberg Sealing Technologies has developed a unique, customized premium sealing solution that combines a sealing lip made of EPDM 302 or Fluoroprene® XP 43 and a reinforcing ring made of PTFE, in record time. The whole sealing solution was designed according to Hygienic Design and all relevant regulations for the food and beverage as well as pharmaceutical industry. Therefore, the seal prevents residues of cleaners or process media from collecting in dead spaces. In addition, the materials involved withstand the demanding requirements for CIP/SIP (Cleaning in Place/Sterilization in Place) processes.

The two elastomeric materials show a hardness degree of 85 Shore A. The combination with the reinforcing ring made of the highly resistant PTFE material, makes the solution extremely pressure resistant. All sealing materials in use are compliant to the EU Reg. 1935/2004, FDA, USP Chapter 87 and 88 and 3-A® Sanitary Standards. The materials show excellent thermal resistance and have very good mechanical properties. While EPDM is mainly used for applications including polar media and water, Fluoroprene® XP is the material of choice for all other applications including fat, flavors or more aggressive media.

The special valve for high-pressure applications, in combination with the high-quality sealing solution, is the perfect choice for the hygienically demanding applications in the food and beverage as well as the pharmaceutical industry.

Do You Already Know Our Other Success Stories?